Articles

Energy Manager

Technology

Taking the pressure off

Time for an update on efforts to improve our residential installation methods

April 23, 2024 By Jon Eakes

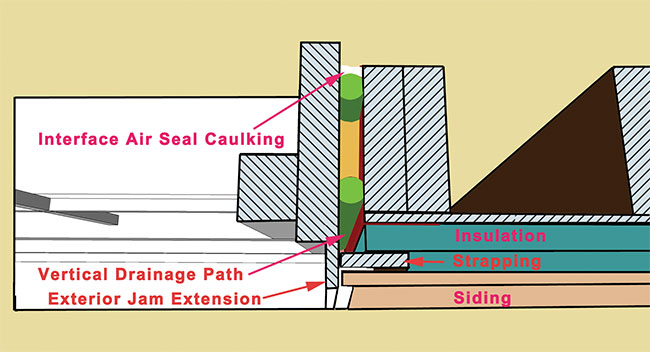

Here’s the simplified concept: use backer rod to create a small space around the window and seal only the inside interface.

Here’s the simplified concept: use backer rod to create a small space around the window and seal only the inside interface. As far back as 2005, the practice of sealing the weather barrier of a house to the frame of the window in an effort to control moisture penetration was questioned enough to justify seven years of research at the Institute for Research in Construction of the National Research Council of Canada.

The guiding principle that came out of that detailed scientific research was, “Don’t try to stop the wind and the rain on the same plane.” Few people paid any attention and window installers all over the country continued to seal the exterior interface between the window frame and the cladding. Because any sealant eventually breaks down (even if it achieved a rare 100-percent seal in the first place) residential window installations still have water penetration problems that lead to rotten and mouldy framing and casements. Face sealing is an unforgiving practice in that any water that gets into the wall cannot get out.

Back in 2014, Joe Lstiburek of Building Science Corporation proposed designs for residential

window pressure equalized window frame profiles. Murry Frank of Constructive Home Solutions, for one, is already teaching these techniques in Vancouver. I’ve added my own wrinkles. Others are stepping forward with similar ideas. In brief, the concept rests on three changes to how we install windows. The first is to leave a small drainage path open behind the weather barrier, allowing air to exchange between the outside and the insulated window/wall cavity. The second is to ensure there are vertical drainage channels on the window frame and a drained sill, using jamb extensions if necessary. Finally, we do not air seal the frame/cladding interface on the exterior of the building but rather on the interior of the window assembly. Water flow control with drainage layers and wind pressure equalization is a forgiving technique which continually dries out the wall. There is lots more to it – for more details visit joneakes.com or see my article in the 2018 fall edition of Fenestration Review, “A better interface.”

After presenting these ideas to several window industry conferences, I succeeded in initiating two college research projects on the use of pressure-equalized principles in the window/wall interface itself, totally independent of the presence or absence of a rainscreen behind the wall siding. The first project was with the BETAC labs of Red River College in Winnipeg, which included quantifying the thermal penalty (if any) for trading off some insulation space in the interface to allow for a pressure-equalized drainage path around the window. The second project was with George Brown College in Toronto specifically on the applicability of pressure equalization in low-rise residential window installations.

George Brown College Research Report

After a shutdown for COVID and thanks to pretty good staff retention, the final George Brown College report on pressure equalization in the residential window/wall interface was the first to be made public in January 2024. The landing page for the George Brown College report and other related and upcoming material, including some video clips from GBC, and a link to Joe Lstiburek’s work on pressure-equalized residential window profiles, can be found on my website.

The tests revealed that, of the window installation configurations used in this study, the best performance of these principles came from an uncompromised air barrier. Water projection simply stopped when plugs were put into the Plexiglas air barrier.

Performance was also best with open drainage paths inside the window/wall interface all around the window. This was true of all the configurations, allowing for a free flow of air and water. This allowed quick, if not instantaneous, pressurization with varying wind pressures and unrestricted flow of water to the drain. Dripping from the jam drainage paths onto the sill was seen visually to be happening only near the weather side of the installation even under strong wind conditions. With pressure equalization, there was no driving force projecting water deeper into the cavity.

The expected but counterintuitive finding was that less water came in with generous sill zone air entry. The larger the sill zone air entry, the less the water penetration.

Line-of-sight baffling was also important. There was no airborne water projection in any window section that was fully baffled, although there was controlled water penetration.

We also looked at elements that compromised this performance. Water penetration was directly proportional to the degree of compromise of the air barrier – open or closed plugs. Open sill zones with no capping allowed the wind to pick up accumulated water on the sill and throw it deep into the window/wall interface. The fully capped window avoided this but required significant spacing where the capping overlapped the wall below the window for quick air flow in…more space than is necessary to let water drain out. We noted it does not take much air flow to pressurize the relatively small drainage paths.

The line-of-sight opening on window #3 was a water-control failure, but a simple unsealed baffle over the crack was a success.

George Brown College kept to the challenge and demonstrated that letting wind into the sill area and up into vertical drainage paths did counteract the driving force of the wind and prevented deep penetration of wind-driven rain. This was a small “proof of concept” study but one that clears the way for a more quantified study.

At the time of the final report, BETAC at Red River College had not yet published their findings on thermal penalties for leaving out insulation to create the window/wall interface drainage path. In March the BETAC report confirmed with data that insulating the interface cavity had little incidence on thermal losses. This gives us free reign to optimize the size of the drainage path for water flow control.

Red River College BETAC Report

I was surprised and discouraged with what was reported in the BETAC study, although it did have one good piece of information on thermal losses. Otherwise, it appears the researchers decided not to pursue my line of inquiry into pressure-equalized window installation at all and instead made sure their experiments were relevant to the current practice of face-sealed installations in Manitoba. I only learned about this change in direction while watching the Fenestration Canada webinar on their final report.

For the thermal loss question, I had proposed comparing insulating the interface from the inside face of the window up to the glazing plane, compared to full insulation and no insulation at all. The intention was to make way for working on water control with a window/wall interface drainage path. The idea of testing thermal losses when the interface is not completely insulated was apparently the only part that stuck as the objective of their project. They devised a model of fully insulating the bottom half of a window and having no insulation in the top half that eliminated any presence of a drainage plane.

The one important result of BETAC’s study was providing quantified data confirming that there was hardly any influence on the thermal performance of the window when comparing a foam-filled window/wall interface cavity to a totally empty cavity. They didn’t test insulating just up to the window glazing plane, which would have even less influence on the thermal performance of the assembly than the minor penalty from no insulation. Their results corroborate the comment by one participant in the Fenestration Canada webinar that the studs and the window frame itself have much more to do with thermal losses than the dead air space of the window/wall interface, as was predicted by the IRC research over 15 years ago. In the same portion of their research, BETAC also concluded that faults in the air barrier compromised everything. These two findings confirmed that the George Brown College pressure equalization study was valid even though no insulation was used at all. It corroborated the GBC conclusions as to the need for an impeccable air barrier.

Perhaps most disappointingly, the BETAC researchers seem to have dismissed out of hand the pressure-equalization concept without studying it. In presenting their results in a Fenestration Canada webinar, they themselves posed the question: “Is it possible to permanently seal water out of a window/wall interface?” Their answer: “When a window is tested for water leakage, the window is face-sealed against water leakage with correct installation of the membrane. A properly face-sealed out-of-the-wall window will function. Water leaks will result from either a deficient window manufacturer or installation. But [with] correct design and simple detailing including effective quality controls in place, [it] can be achieved.”

This answer was speculation based on short-term research to answer a long-term question. What became evident in the webinar was that they simply didn’t believe in drainage planes or pressure equalization and chose to make sure that this research would not challenge the status quo of surface-sealing window installations. They did, however, answer an important question by documenting that there was no significant thermal penalty when leaving some interface space uninsulated to allow for the creation of a wind-pressurized water control drainage plane.

Research should dare to study promising alternatives to lead the way to improvements in building science. I am certain that BETAC at Red River College, with their impressive technical equipment, does an excellent job of testing to standard protocols. However, we are going to have to look elsewhere if we are looking for research leading to innovations in building technology. For me, this BETAC research project was a lost opportunity that delayed me for several years from initiating the research elsewhere that I feel needs to be done.

Looking forward

The building codes and standards provide for many possibilities in installing windows, although they are moving toward better water control than simple face sealing because, with face sealing, when water does get in it has no way out. The National Building Code already requires provisions for drainage and is proposing in the next cycle, full internal wrapping of the rough window opening. Both the next NBC and the CSA A440.4 to .5 are looking at removing insulation in favor of drainage. Organizations familiar with Ontario’s code process are saying the province is likely to pick up on all of this. Already, both codes and standards permit everything I had proposed in this research. So adapting pressure equalization to low-rise wood frame housing is simply the missing piece to make this drainage plane into a dynamic water control system. Since it is coming, we might as well study how to apply these ideas before they are forced upon us.

We still have much to do to quantify all of this with the objective of helping manufacturers, installers and inspectors to move from theory to practice with confidence, away from face-sealing to using the wind to control the rain. The George Brown College research tells us this is possible.

For more information

- IRC Construction Technology Updates #76 and #80

- nrc-publications.canada.ca

- George Brown College and Red River College (BETAC) final reports webinars

- fenestrationcanada.ca/videos

- Links to the above and more at joneakes.com

Print this page