Articles

Fabrication

The laminate advantage for window lineal finishes

Laminates offer texture, speed and durability as window lineal finishes.

October 19, 2017 By Amber Gunderson Chameleon Topcoatings

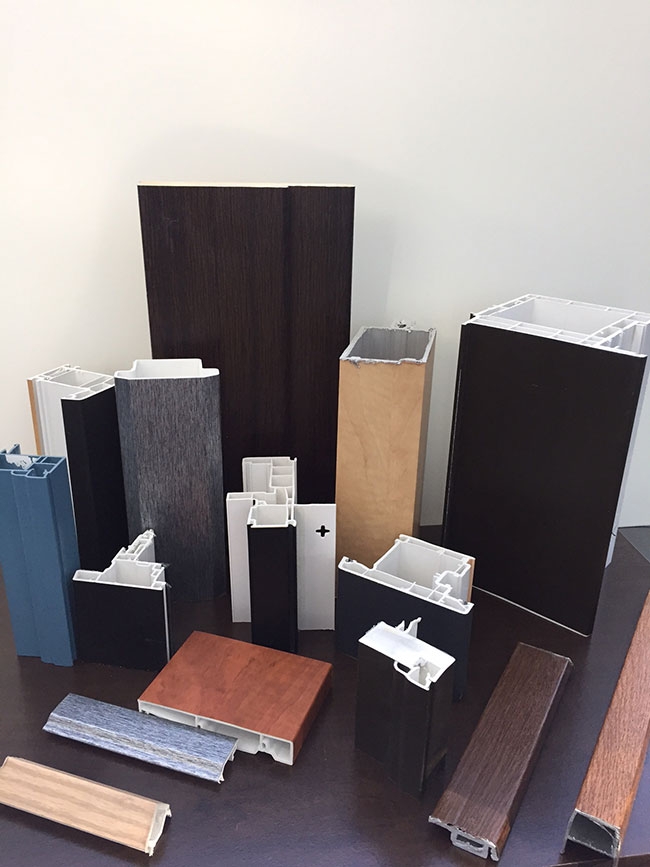

Lamination can be a great finish option for windows. Laminate is a multi-layer construction of high-grade materials. It is constructed to ensure an extended resistance to weather conditions and colour stability. One of the greatest features of laminate is its scratch-resistance.

Also it is available in many different types of realistic woodgrain designs, as well as a multitude of solid colours and embossed finishes. Laminate is thin, with a final thickness of about nine to 10 microns, which makes it easy to join window components together and give detail to your window profile. Laminates, when damaged, can easily be repaired in the field with a repair kit. There is very little waste, as a typical run will require only two feet to be kept back for testing per AMMA standards and machine setups can re-use the same profile many times.

Lamination can only happen when the window profiles are in lineals. But do not worry – screen bar, aluminum and wood components can also be laminated. The biggest request for laminate is when the window manufacturer is selling a high volume of one or a few select colours. A profile can be laminated with more than one colour option for the same price, thereby eliminating large inventories. The scratch-resistant coating on laminate is a bonus and helps reduce waste. But for a small additional charge, if requested by a customer, a laminate-friendly protective tape can be added by the machine.

Lamination is also ideal for projects. On average, lamination will cost 30 per cent less then paint, even when done in-house. Contract laminators will run your profiles, stack them neatly into carts or bags and have them ready for shipment back to your plant on a speedy timeline because the lamination process is much faster than paint.

The laminates available today on the market are of the highest quality and the most realistic woodgrains. There are also veneers and other stainable laminates that can be used on the interior of PVC windows to give a rich look that cannot be achieved by paint. They have UV protectors in them and scratch-resistant coatings. The stainable laminates available allow the manufacture to inventory PVC and laminate the interior without needing to stock real wood windows. Stainable laminate is very realistic and can be finished just like wood by the homeowner. Now your customer can use their window without the worry that the windows will chip, warp, rot or have cracking. Most of the time, people looking at the house do not even realize it’s not a real wood window.

Because wood can splinter and crack, painting a window will not cover these issues and will also require maintenance and re-application year after year. Laminates last for years and years.

Lamination performance has been documented for more than 35 years in the global market. In the eastern part of the world lamination is a highly respected trade requiring special schooling. Lamination and solvent paints are now very durable, flexible and heat-reflective compared to the products 10 years ago. The industry has come along way and in today’s market we can rest assured we are adding value and quality.

Print this page

Leave a Reply