Articles

Dealer’s Corner

The freedom to quote

Dealer ERP software can broaden your options.

July 13, 2015 By Sherif Eldibany

Dealer ERP software really comes into its own on complex custom jobs. With the right system architecture, quoting individual components can be easily integrated.

Dealer ERP software really comes into its own on complex custom jobs. With the right system architecture, quoting individual components can be easily integrated. Manufacturer-supplied quoting/ordering software packages do make dealers’ lives easier by allowing dealers to accurately and quickly quote products and easily place their orders with the supplier.

There is, however, a catch: dealers can only quote one manufacturer’s product at a time. So what happens if a dealer wants to quote products from multiple manufacturers? The answer is they cannot, at least not easily.

Many dealers who offer products from multiple suppliers experience lots of frustration conducting their day-to-day business using manufacturer-supplied quoting software. The process of pricing, providing the prospect with a single quote, ordering from suppliers and recording the transaction for accounting has become tedious and time-consuming. To quote a project, dealers often need to use two or three different quoting and ordering packages to quote all the products required for a job. Then parts of the quotes must be combined into a single document that is presented to the customer. If the customer accepts the quote, the dealer has to update the accounting system, create the order, create an in-house purchase order, generate work orders for services and value-added products, place purchase orders with their suppliers using the provided software, then generate invoices from the accounting packages.

Some quoting packages allow dealers to enter items they buy from other manufacturers as simple line items. While this helps the dealer provide clients with an all-inclusive quote document, it presents several issues to the dealer. The first concern is privacy. What information will the supplier who provided the software get to see? The dealer could be inadvertently sharing proprietary pricing and product information with their supplier’s competitor. Regardless, the dealer will still need to price the other items manually or by using other software. While the boom in providing quoting packages has made sense to manufacturers, it has not helped to reduce the complexity of day-to-day workflow for dealers.

Solution: dealer ERP

As opposed to quoting packages, dealer ERP software can be a complete dealer-centric software solution that runs the dealer’s day-to-day business. These systems provide the dealers with a single package in which they can create quotations that include products from multiple manufacturers, combines other made-to-order products (such as entry doors, siding and roofing) and adds other value-added products such as trim or installation material and services such as installation and disposal.

Dealer ERP software is typically equivalent to the enterprise-grade software that a manufacturer would use. It allows the dealer to offer integrated CRM functionality to help manage the sales process from the lead to the sale and to manage all the after-sale interactions. As mentioned, it incorporates a single software solution in which customer quotations can be created for all products and services and converted to orders.

It can also keep track of all costing information, including the purchase price of all products, the manufacturing cost of products fabricated in-house and the cost of services to generate an accurate financial analysis. Dealer ERP can track the complete sales cycle and provide useful sales management reports and statistics. It can create service work orders for installation and after-sale services. Dealers can use it to create manufacturing shop floor work orders for those items that are fabricated in-house such as entry doors, trim and even items that are glazed in-house. ERP software can show the scheduling of service and fabrication work and coordinate it with scheduling of purchases. It can create purchase orders to suppliers but also handle inventory issues and receipts. Finally, Dealer ERP can integrate into the dealer’s accounting software to provide a complete cycle including tracking of accounts receivable, payable and even commissions payable.

Despite the superiority of ERP systems, it is still rare for manufacturers to provide them to their dealer network. There are two main reasons for this: product loyalty and cost.

Don’t fear competition

A manufacturer’s ultimate goal must be to help dealers sell as much of their product as possible. However, it is unlikely that they can force a dealer to exclusively sell just their products unless they provide enough incentive for them to do so. To win a dealer’s business and loyalty, manufacturers need to provide them with benefits that make them loyal. This means good products at a great price with exceptional service. Providing quoting software will not make much difference one way or the other compared to these factors. Manufacturers should imagine how much more loyalty they could gain if they provided the type of business tools that actually help dealers run their day-to-day business.

Counting cost

Licensing costs for ERP software are high. However, there is open source (license-free) and low-cost commercial software available for the industry. These solutions cover most of the functionality that dealers and manufacturers require out of the box with no or low-cost license fees. The rest can be developed to match the dealer’s needs exactly.

Then there are implementation costs. All software carries an implementation cost. It is not cheap to implement ERP software whether you are a manufacturer or a dealer. But again, well-designed software allows for rapid, and therefore inexpensive, implementation. It is also reasonable for the manufacturer to ask the dealer to contribute to any implementation costs for things beyond the basic price book and basic software functions. The key for manufacturers is to strike a deal with a software vendor so their dealers can obtain the software through them cheaper than what they would have had to pay otherwise. Open source software provides dealers and manufacturers with ERP software at very low entry costs due to free licensing and shared development costs. But even with open source software, the total cost to the dealer will always be cheaper if the software is offered through manufacturers as they typically absorb some of the implementation costs.

Reaping the benefits

At the end of the day, what is really important is the bottom line. In this case, the benefits realized by manufacturers can be summarized in two main areas. The first is reduced cost of doing business. By providing quoting packages, manufacturers reduce order entry costs by allowing the dealer to do their own quote/order entry and importing those orders directly into the manufacturing system. They also reduce quotation and ordering errors by eliminating re-entry of orders from dealers and by making the dealers accountable and responsible for their own order-entry errors. To make sure they realize these benefits, manufacturers should ask their dealer ERP vendor to export orders in a format compatible with their own ERP. They also need to ask their ERP vendor to allow import order in generic format from the dealer software. But probably the easiest and most realistic way is to ask the dealer to enter the items they are buying into the manufacturer’s system as well as their own ERP system, maybe for an extra discount or other benefits.

The second benefit to manufacturers in providing dealer ERP software is increased sales. Manufacturers provide dealers with quoting software to encourage them to sell the products they make. The problem is that every manufacturer, including all their competitors, had the same idea. As a result, providing a quoting package does not (at least not any longer) guarantee increased sales. Yet, it is still very important that manufacturers provide an easy way of quoting and ordering their products.

If a manufacturer starts working with a dealer that already has an ERP solution they can simply add their price book to the ERP system the dealer is using. It is relatively inexpensive to do so in well-designed software. This will help the dealer quote products with little effort and it will put the manufacturer at par with other suppliers who have added their price books in the dealer’s system. It can be surprising how easy (and inexpensive) it is to maintain a price book in multiple software packages.

Price book styles and structures

The key to easily implementing and maintaining price books in many ERP systems is the structure of the price sheets. There are three pricing styles that are very common.

Marked-up cost pricing is the most aggressive pricing strategy and is often used in very competitive markets. In terms of software, this requires that a complete bill of materials (BOM) be generated, the cost calculated, and a mark-up applied to each component. Sometimes, the mark-up is different for different families of parts, for example, the mark-up on glass may be different than the mark-up on extrusions or hardware. This pricing model is more common these days as manufacturers have to offer more aggressive pricing. In terms of level of difficulty, the implementation of marked-up cost pricing is relatively easy for the manufacturer since the manufacturing software always calculates the complete BOM.

Implementing this type of pricing for dealers represents a significant challenge as the dealer’s ERP software has to execute the manufacturer’s complete BOM to obtain a price. The actual cost of manufacturing will always remain hidden from dealers, who will only see their cost of buying the products from the manufacturer. While this is more difficult, some software, including some existing open source packages, do this. For instance, the dealer ERP software asks the manufacturer’s ERP to execute the BOM for a window design built by the dealer. The manufacturer’s ERP calculates a cost, marks it up to reach a price, discounts it by the dealer’s factor, and sends the dealer’s software the cost of the product. The dealer’s software then applies its own mark-up, less the customer discount (if any), to arrive at a selling price. No data installation or updates occur on the dealer’s system, and the actual data for costing remains on the supplier’s server and totally hidden from the dealer. Many manufacturers prefer this method for their commercial grade product lines offered at very competitive prices, while for their other retrofit/retail product lines they use the third pricing method discussed below. The disadvantage of marked-up cost pricing is the dealer and the manufacturer have to use the same ERP or the manufacturer has to duplicate his BOM in the dealer’s ERP and hide the content from the dealer – which can get costly to maintain.

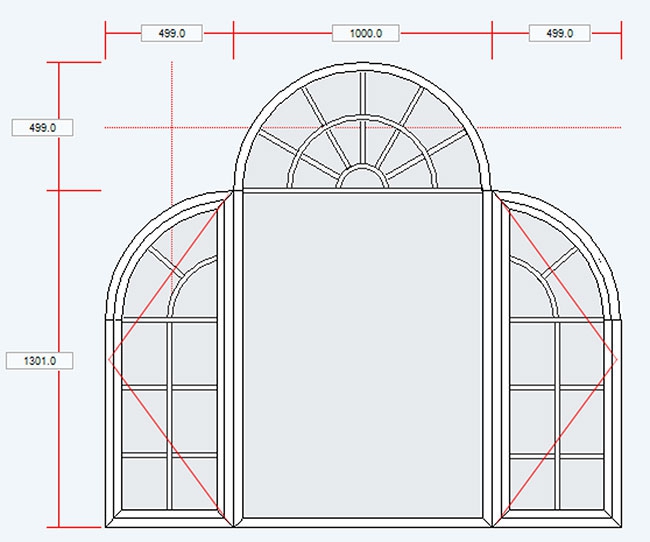

By standard design pricing, we mean a specific configuration of a window or door, for example, fixed window over a slider combination, or two coupled single-hung units. In these types of price books, manufacturers offer a design (fixed over sliders, for example), followed by a list of sizes and columns of prices representing base prices for each size. There are also option prices for each size, even glass prices and grid patterns for each size.

As the construction boom of the early 2000s slowed down, this style of price book became less and less common. There are, however, many larger manufacturers that still use it. While there are many merits to this pricing structure, as it can be used to closely reflect marked-up cost pricing, it is the most time-consuming and tedious price structure to implement in software as it may require hundreds of tables and columns to add and maintain. It is always best to keep price styles and structures as simple as possible, by following some basic rules. If each window is individually made and then mulled together, use individual window pricing, plus coupler charges. Use option pricing based on area or linear footage. Grids should be based on a per-lite price, area or something similar, plus customization charges. If the windows are made with a common frame using mullions, or if you use standard design based pricing, attempt to minimize the number of matrices by keeping the option, glass and grid pricing as add-ons based on square footage or lineal footage. Alternatively, you could price each window individually, add the prices together, then deduct X amount per mullion. In this scenario, keep the options, glass and grid pricing as add-on pricing based on square footage or lineal footage. There are many other creative ways clients have come up with to simplify their price books for products with common frames.

Individual window pricing plus options sheets is by far the easiest and simplest pricing style. It works well for manual pricing, and is extremely easy to set up in software. Under this pricing style, windows and doors are priced individually (by united inch, square footage, size matrix/table, etc.) then options, mulling charges, glass options and whatever other charges are needed are added to the base window prices. The resulting price book is often only one or two pages long.

Discounts and updates

With dealer ERP solutions, the manufacturer supplies one price book to all dealers. Each dealer then sets his own discount into the ERP system in order to get the actual cost. Dealers can sell products based on the manufacturer list prices or they can, in competitive situations, apply a mark-up to their costs. Dealers can also apply discounts by type of product or even by option. This enables the manufacturer to offer competitive prices to specific dealers while maintaining only one price book.

Dealers that have special pricing agreements with their suppliers can go as far as setting and maintaining their own price books.

With dealer ERP software, responsibility for price books updates falls on the shoulders of the dealer. In most cases, if the manufacturer’s price book is well-designed, this is an easy task and is usually covered by the maintenance and support agreements negotiated with their software vendors. In other cases, price books can be maintained for the manufacturer by the software developer for a negotiated monthly or annual fee.

Dealer solutions do not need to be expensive software as there are license-free, open-source alternatives. Manufacturers should never put obstacles in the way of a dealer’s efforts to implement their own ERP. If the dealer software is able to interface with a manufacturer’s ERP, then great, but even if it doesn’t, the manufacturer should offer the dealer incentives to enter their purchase orders into the software provided. Most dealers will be very happy to do so as long as it makes business sense to them.

Sherif Eldibani is the founder of OpenJanela. He has 26 years’ experience providing software solutions to the fenestration industry.

Print this page

Leave a Reply